While most solar panel manufacturers offer a ten year materials warranty rec provides a maximum of 20 year warranty against any defects in their solar panels.

Arsenic in solar panel manufacturing.

In 2011 hydrofluoric acid used by the company for solar panel manufacturing contaminated river water killing hundreds of fish and dozens of pigs.

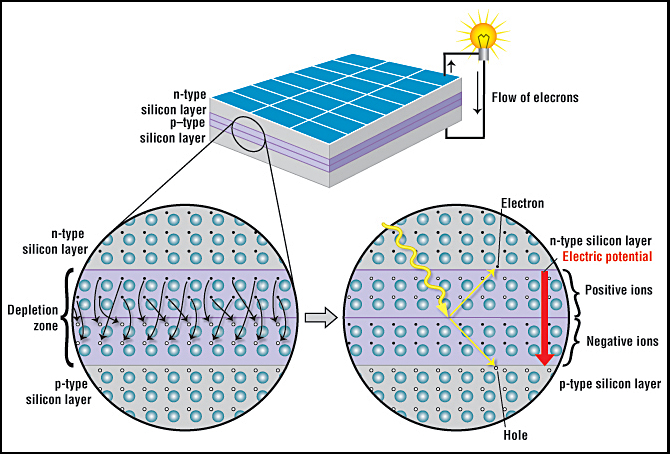

Gallium arsenide gaas it is a iii v direct band gap semiconductor with a zinc blende crystal structure.

Yet manufacturing all those solar panels a tuesday report shows can have environmental.

Environmental scientists and solar industry leaders are raising the red flag about used solar panels which contain toxic heavy metals and are considered hazardous waste.

With recycling expensive.

1 24 the electronics industry uses 5 of the arsenic produced to make gallium arsenic semiconductors for use in cell phones solar panels and light emitting diodes leds and the remaining 15 is used in glassmaking and to harden metal alloys in ammunition solders and bearings.

Gaas is often used as a substrate material for the epitaxial.

Here is a partial list eight of fifty of chemicals associated with solar photovoltaic pv manufacturing and disposal.

Cost most of rec s solar pv systems are typically priced between 2 44 and 3 06 per watt which makes them a strong value in the market for home solar panels.

Gallium arsenide is used in the manufacture of devices such as microwave frequency integrated circuits monolithic microwave integrated circuits infrared light emitting diodes laser diodes solar cells and optical windows.

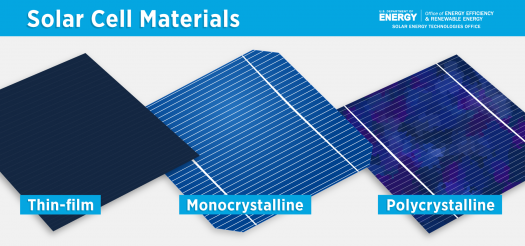

Arsenic cadmium telluride hexafluoroethane lead and polyvinyl fluoride are just some of the chemicals used to manufacture various types of solar cells.

Waste from solar panel production can contain high levels of soluble as 5 which fortunately is over 50 times less harmful than as 3.

It is anything but safe when all factors are considered.

As the world seeks cleaner power solar energy capacity has increased sixfold in the past five years.

They re on track to achieve efficiency rates of.

None of this poses much if any threat.

Most manufacturers recycle this waste to make more polysilicon.

.jpg)